Mine Exploatation & Engineering

Driving Sustainable Mining Solutions, Together – Your Partner for a greener Future!

MINING IN KEBEMER REGION – SENEGAL

IMPLEMENTATION YEAR: 2018

LOCATION: KEBEMER REGION (Senegal)

ACTIVITY: Ore Characterization, Beneficiation, Flowsheet Development

In Kebemer, Senegal, under the exceptional lead of Dr. Eng. Anna Podolak, we played a pivotal role in the development of a beneficiation plant for phosphate ore. Our scope of work encompassed crucial engineering tasks, including

ore characterization, beneficiation, and flowsheet development.

To kickstart the project, GC conducted a scoping metallurgical test program on samples extracted from the Kebemer phosphate deposit. Four carefully labeled samples, B1/E, B1/W, B2/E, and B2/W, were prepared for metallurgical testing. The ultimate goal was to achieve an Apatite concentrate with a P2O5 content of 30% from each ore sample.

The comprehensive test program involved thorough ore characterization, beneficiation processes, and the development of optimized flowsheets. Through rigorous bench testing, we successfully produced a concentrate with an average grade of 33% P2O5 from ore samples containing an average of 18% P2O5. The overall recovery of phosphate reached 60%, although it was slightly lowered due to desliming losses prior to flotation. Notably, the slimes rejection resulted in the removal of 54% of iron and 74% of aluminum. We effectively eliminated silica through desliming and subsequent flotation.

While the Kebemer ore yields a high-grade concentrate, it also contains a significant amount of iron. If the iron content in the concentrate leads to a Minor Element Ratio (MER) exceeding 0.1, challenges may arise in phosphoric acid and DAP production. Furthermore, elevated iron levels can potentially hinder the manufacturing processes of phosphoric acid and DAP.

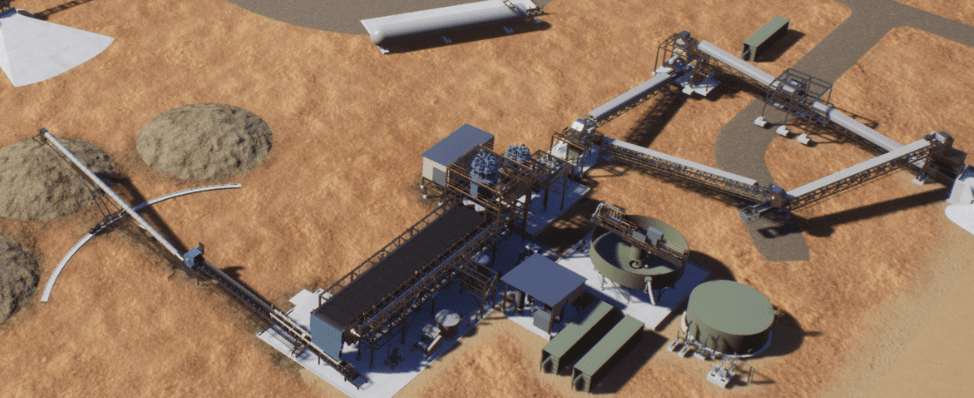

Based on the four beneficiation flowsheets developed through our testing, we have designed a Proposed Process Block Flow Diagram. This diagram outlines the optimized processes that maximize the efficiency of the beneficiation plant.

Through our expertise and dedication, GC has contributed to the advancement of the Kebemer beneficiation project. We remain committed to delivering innovative solutions that enhance the efficiency, quality, and profitability of phosphate ore processing.

Mine Exploatation

Driving Sustainable Mining Solutions, Together – Your Partner for a Greener Future!

MINING IN Kebemer – SENEGAL

IMPLEMENTATION YEAR: 2018

LOCATION: Kebemer (Senegal)

ACTIVITY: Geological exploration, well drilling, feasibility study, mine design

In 2018, we proudly completed the construction of our mine in Kebemer Region, Senegal. Our team’s meticulous planning and dedication led to the seamless integration of the mine into the local landscape. This achievement showcases our commitment to responsible mining practices and our contribution to the sustainable growth of the Thies community.

Transforming Mining in Kebemer, Senegal: A sustainable Milestone.

This project:

- Execution of a comprehensive geological survey plan, involving thorough investigations and assessments of the area.

- Drilling a series of wells to gather crucial geological data and samples for analysis.

- Conducting a full chemical and geological analysis of the deposit, providing valuable insights into its composition and characteristics.

- Compiling a detailed geological report with deposit calculations, offering a comprehensive understanding of the deposit’s potential.

- Performing a feasibility study of the mine, assessing its economic viability and operational feasibility.

- Preparing and developing advanced mining technology tailored to the specific requirements of the project.

- Designing the mine layout, ensuring optimal efficiency and productivity.

These activities summarize the key steps in the mining process!

In the past, under the exceptional supervision of Dr. Eng. Anna Podolak, Groupe Curie successfully executed the full exploration phase for the company holding the exploration license. This encompassed conducting a comprehensive geological survey plan, drilling a series of wells, and performing full chemical and geological analysis of the deposit. Based on the gathered data, a detailed geological report with deposit calculations was generated.

Additionally, Dr. Eng. Anna Podolak oversaw the feasibility study conducted by the GC to evaluate the mine’s potential and viability. They also facilitated the process of converting the company from an exploration entity to an exploitation company, establishing a mining entity for the project. The GC, under the supervision of Dr. Eng. Anna Podolak, played a vital role in designing the mining technology and overseeing the construction of the mine. They ensured the precise implementation of the plans, leading to the successful opening of the deposit and the start-up of mining operations.

The mine has been designed to have a production capacity of 1,500,000 tons of phosphate per year. Our dedicated team of experts worked diligently to accomplish these tasks, setting the stage for a successful and sustainable mining operation in the region. With Dr. Eng. Anna Podolak’s expertise, the completed project stands as a notable reference, demonstrating Groupe Curie’s commitment to excellence and expertise in the mining industry.

Mine Exploatation

Driving Sustainable Mining Solutions, Together – Your Partner for a Greener Future!

MINING IN Matam – SENEGAL

IMPLEMENTATION YEAR: 2018

LOCATION: Matam (Senegal)

ACTIVITY: Geological exploration, well drilling, study, design, construction

In Matam, Senegal, Cimec, under the lead of Dr. Eng. A. Podolak, undertook the construction of a phosphate mine, led by Dr. Eng. Anna Podolak. Our scope of work included conducting a detailed geological survey, performing a comprehensive feasibility study, and overseeing the conversion of the company to a mining entity. We designed and constructed the mine, opened the deposit, and successfully initiated mining operations. With a capacity of 1.5 million tons of phosphate per year, our project exemplifies our commitment to excellence and sustainable resource management.

Transforming Mining in Matam, Senegal: A sustainable Milestone.

Discover our transformative mining projects in Senegal, where we have executed comprehensive geological surveys, feasibility studies, and cutting-edge mining technologies. With a focus on sustainability and technical excellence, we have successfully established and operated phosphate mines, contributing to regional growth and environmental preservation. Experience the impact of our exceptional team, led by Dr. Eng. Anna Podolak, as we redefine mining excellence in Senegal.

This project:

- Comprehensive geological survey and analysis

- Feasibility study, including environmental and social impact assessment

- Conversion of the company from exploration to exploitation entity

- Design and construction of advanced mining technology

- Construction of the phosphate mine

- Opening of the deposit for mining operations

- Start-up and management of mining activities

- Achieving a remarkable production capacity of 1.5 million tons per year

These activities highlight our expertise in geological assessment, project feasibility, and successful implementation of mining operations.

In the region of Matam, Senegal, CIMEC has made significant strides in the mining sector. Our projects in Matam have contributed to the region’s economic growth, fostering job opportunities and driving local development.

Through meticulous planning and execution, we have established mining operations that prioritize sustainable resource extraction. Our commitment to environmental stewardship ensures the preservation of Matam’s natural beauty and biodiversity.

With our expertise in comprehensive geological assessments, feasibility studies, and advanced mining technologies, we have successfully unlocked the potential of Matam’s mineral resources. By adhering to stringent safety protocols and industry best practices, we have created a foundation for responsible and efficient mining operations.

CIMEC is proud to be a partner in Matam’s journey towards a prosperous and sustainable future. Together, we are building a legacy of success, community empowerment, and environmental sustainability.

Mine Exploatation

Driving Sustainable Mining Solutions, Together – Your Partner for a Greener Future!

MINING IN Thies – SENEGAL

IMPLEMENTATION YEAR: 2018

LOCATION: Thies (Senegal)

ACTIVITY: Geological exploration, well drilling, study, design, construction

In Matam, Senegal, Cimec AG undertook the construction of a phosphate mine, led by Dr. Eng. Anna Podolak. Our scope of work included conducting a detailed geological survey, performing a comprehensive feasibility study, and overseeing the conversion of the company to a mining entity. We designed and constructed the mine, opened the deposit, and successfully initiated mining operations. With a capacity of 1.5 million tons of phosphate per year, our project exemplifies our commitment to excellence and sustainable resource management.

Transforming Mining in Thies, Senegal: A sustainable Milestone.

Experience the impact of our exceptional team, led by Dr. Eng. Anna Podolak, as we redefine mining excellence in Senegal.

This project:

- Geological Survey: Execution of a comprehensive geological survey plan for the exploration concession.

- Drilling: Conducting a series of well drilling activities to gather essential data.

- Chemical and Geological Analysis: Performing detailed chemical and geological analysis of the deposit.

- Geological Report: Preparation of a comprehensive geological report with deposit calculations.

- Feasibility Study: Conducting a feasibility study to assess the viability and potential of the mine.

- Company Transformation: Facilitating the process of converting the company from an exploration entity to an exploitation company and establishing a mining company.

- Mining Technology Design: Designing the mining technology and infrastructure required for the operation.

- Mine Construction: Executing the construction of the mine according to the approved design.

- Deposit Opening: Opening the deposit for mining operations.

- Start-up: Initiating the mining operations and ensuring a successful start.

In the vibrant region of Thies, Senegal, CIMEC has made significant strides in the mining sector. Our projects in Matam have contributed to the region’s economic growth, fostering job opportunities and driving local development.

Through meticulous planning and execution, we have established mining operations that prioritize sustainable resource extraction. Our commitment to environmental stewardship ensures the preservation of Matam’s natural beauty and biodiversity.

With our expertise in comprehensive geological assessments, feasibility studies, and advanced mining technologies, we have successfully unlocked the potential of Matam’s mineral resources. By adhering to stringent safety protocols and industry best practices, we have created a foundation for responsible and efficient mining operations.

CIMEC is proud to be a partner in Matam’s journey towards a prosperous and sustainable future. Together, we are building a legacy of success, community empowerment, and environmental sustainability.