Industrial Engineering

We plan and realize industrial automation systems for wind and solar installations

Water Ressource Engineering

We plan and realise water ressource services from plaining till construction

Sustainable Engineering

We build efficient & smart solar, wind and hydro power plants

Execution Planning

We plan sustainable solar and wind solutions for existing and new projects

Contact us today to learn more about our Cleantech installations and how we can support your clean energy initiatives!

CLEANTECH TECHNOLOGIES

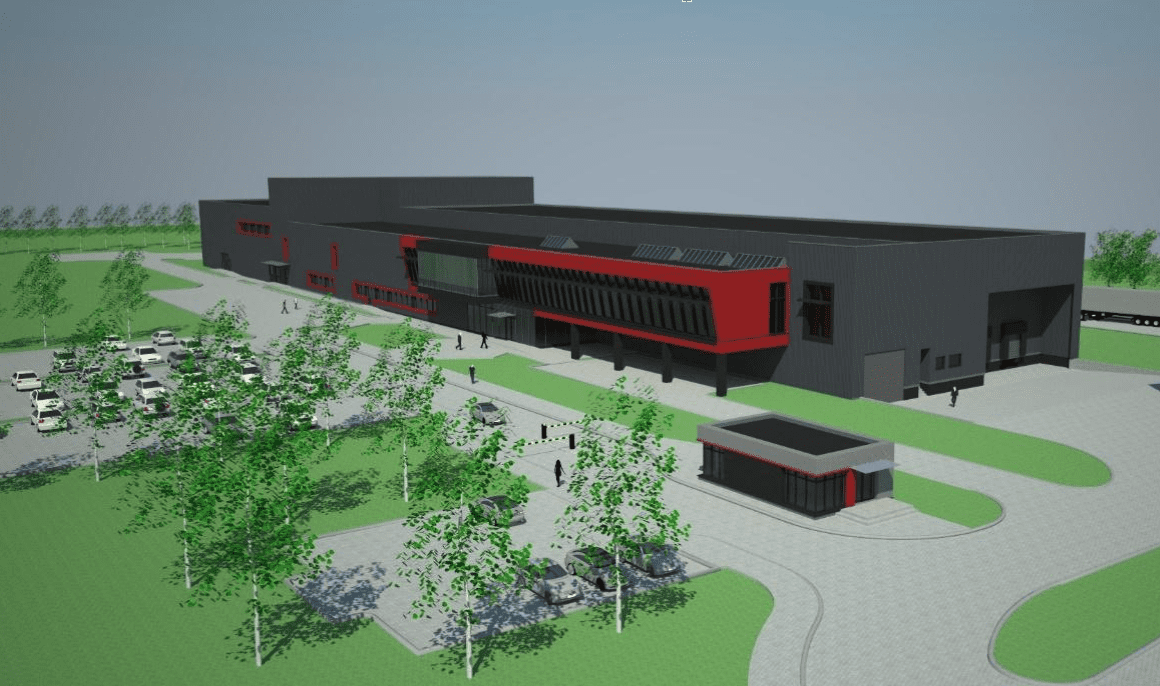

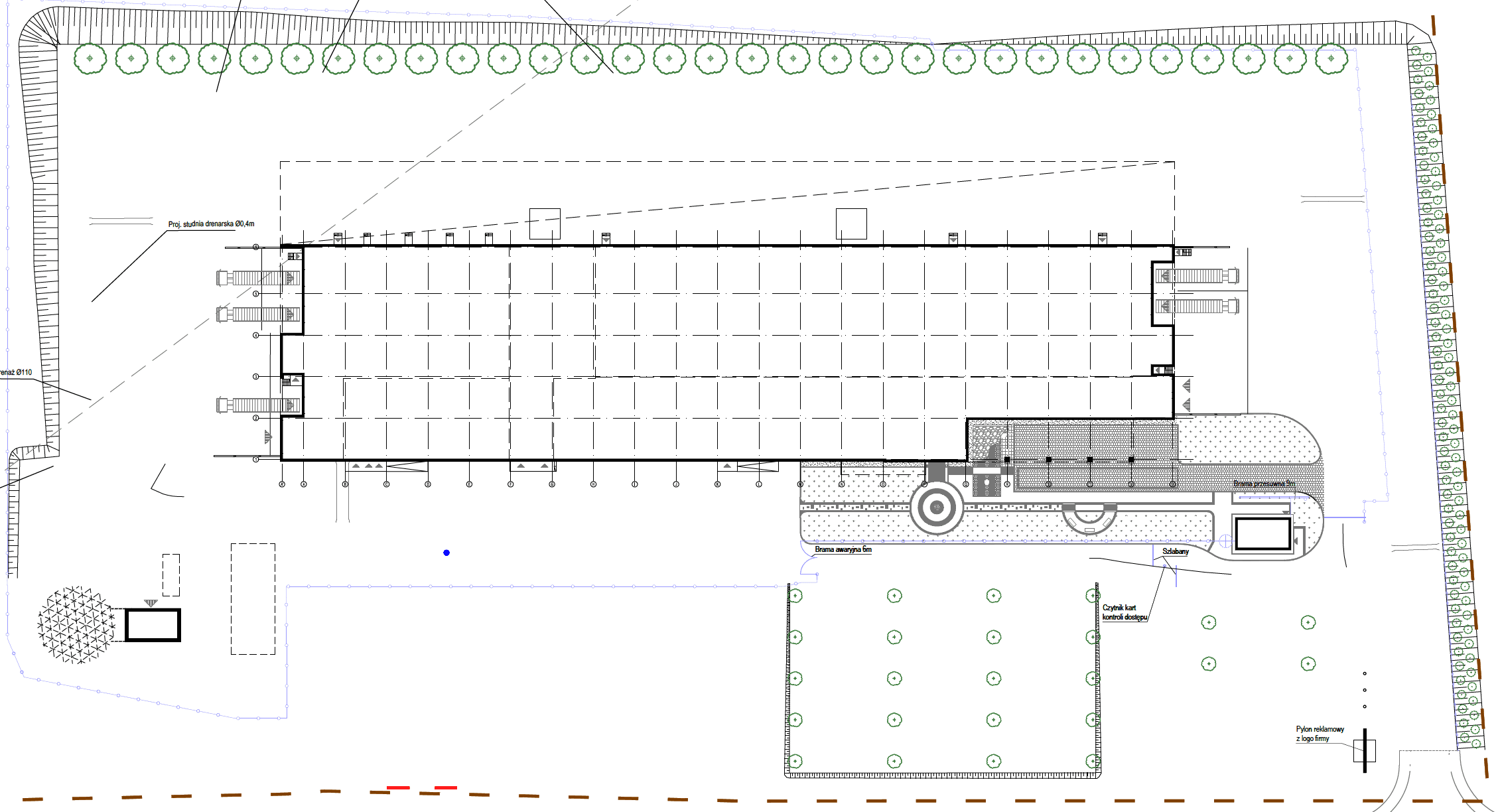

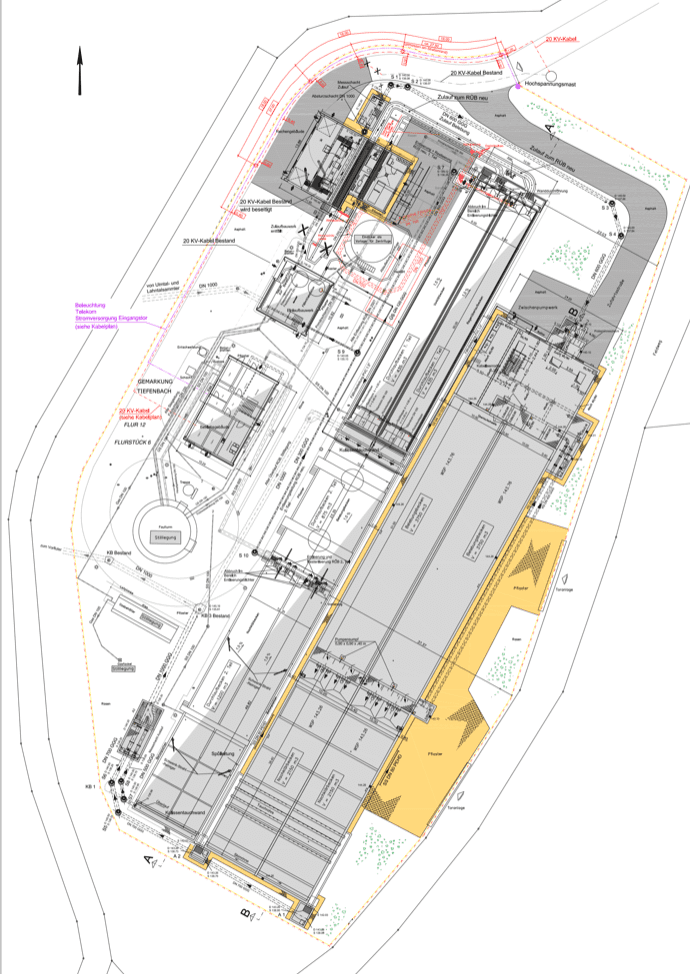

FOOD PROCESSING PLANT

Integration of Clean Technologies for Sustainable Resource Planning and Installation in a Food Processing Facility in Poland

FOOD PROCESSING PLANT

LOCATION: Warmia-Masuria (Poland)

ACTIVITY: Planning, execution and construction

The building, constructed by CIMEC under the lead of Dip.Ing. A. Zoerb is a food processing facility with an office complex in Poland, covering a total area of approximately 6000 square meters. The entire complex was designed with sustainability in mind, particularly focusing on energy efficiency and conservation. The complex incorporates a variety of environmentally friendly and resource-efficient measures, including the installation of a photovoltaic system and 2 wind turbines to harness renewable energy sources. These systems provide the required energy for the office area and lighting in the parking lot. The integration of cleantech solutions, such as wind energy, solar energy, and other environmentally friendly technologies, plays a crucial role in the planning and installation of sustainable resources for the food processing facility in Poland.

By incorporating renewable energy sources, such as the photovoltaic system and wind turbines, the facility can significantly reduce its reliance on conventional energy sources and contribute to a greener and more sustainable future. This not only helps in conserving non-renewable resources but also reduces greenhouse gas emissions and mitigates the impact of climate change. Furthermore, the emphasis on energy efficiency, water-saving measures, and chemical-free water treatment demonstrates the commitment to responsible resource management and sustainable practices.

Harnessing Wind and Solar Energy for Energy Efficiency and Environmental Conservation

This project:

The integration of cleantech solutions such as wind energy, solar energy, Nitrogen, Oxygen and other environmentally friendly technologies plays a crucial role in the planning and installation of sustainable resources for the food processing facility in Poland. By incorporating renewable energy sources, such as the photovoltaic system and wind turbines, the facility can significantly reduce its reliance on conventional energy sources and contribute to a greener and more sustainable future. This not only helps in conserving non-renewable resources but also reduces greenhouse gas emissions and mitigates the impact of climate change. Furthermore, the emphasis on energy efficiency and energy savings demonstrates the commitment to responsible resource management and cost-effectiveness. Overall, the adoption of cleantech and renewable energy systems showcases the importance of sustainable practices in the context of food processing and highlights the positive environmental and economic benefits they can bring.

Under the exceptional leadership of Cimec and with the expertise of Dipl. Ing. A. Zörb, the meticulously planned and executed Food processing plant prioritized key technical aspects:

- Design and construction of the food processing facility and office complex: The initial step involved designing and constructing the facility, considering sustainability and energy efficiency as key factors.

- Incorporation of energy-efficient measures: Various energy-efficient measures were implemented throughout the facility, including efficient indoor and outdoor LED lighting, water-saving faucets, and above-standard building insulation. These measures help reduce energy consumption and optimize resource usage.

- Installation of a photovoltaic system: A photovoltaic system was installed to harness solar energy and generate electricity for powering the office area and other electrical needs within the facility.

- Integration of wind turbines: Two wind turbines were installed to capture wind energy and convert it into electricity. These turbines provide additional renewable energy to meet the power requirements of the facility.

- Implementation of sustainable water treatment and energy monitoring systems: A chemical-free water treatment system was implemented to ensure eco-friendly water management practices. Additionally, an energy monitoring system was installed to track and optimize energy consumption, promoting efficient resource usage.

These activities collectively contribute to the overall sustainability of the facility by reducing reliance on conventional energy sources, minimizing carbon footprint, and promoting the use of renewable energy technologies.

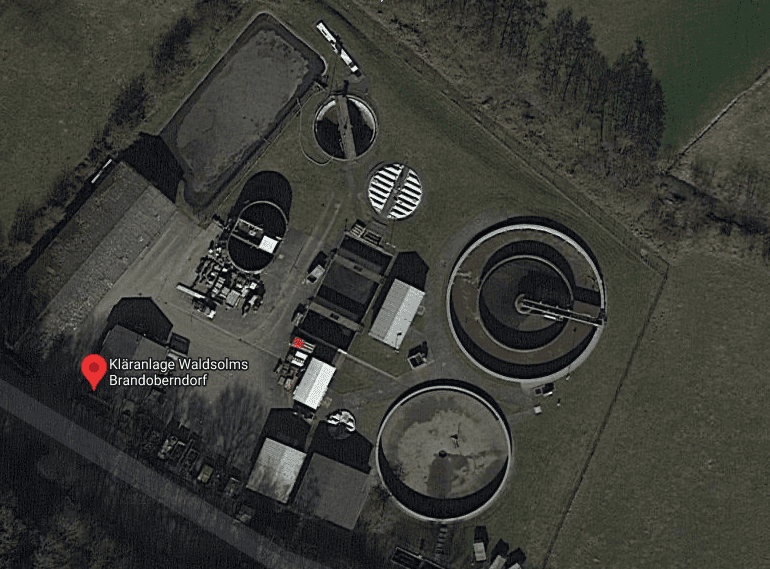

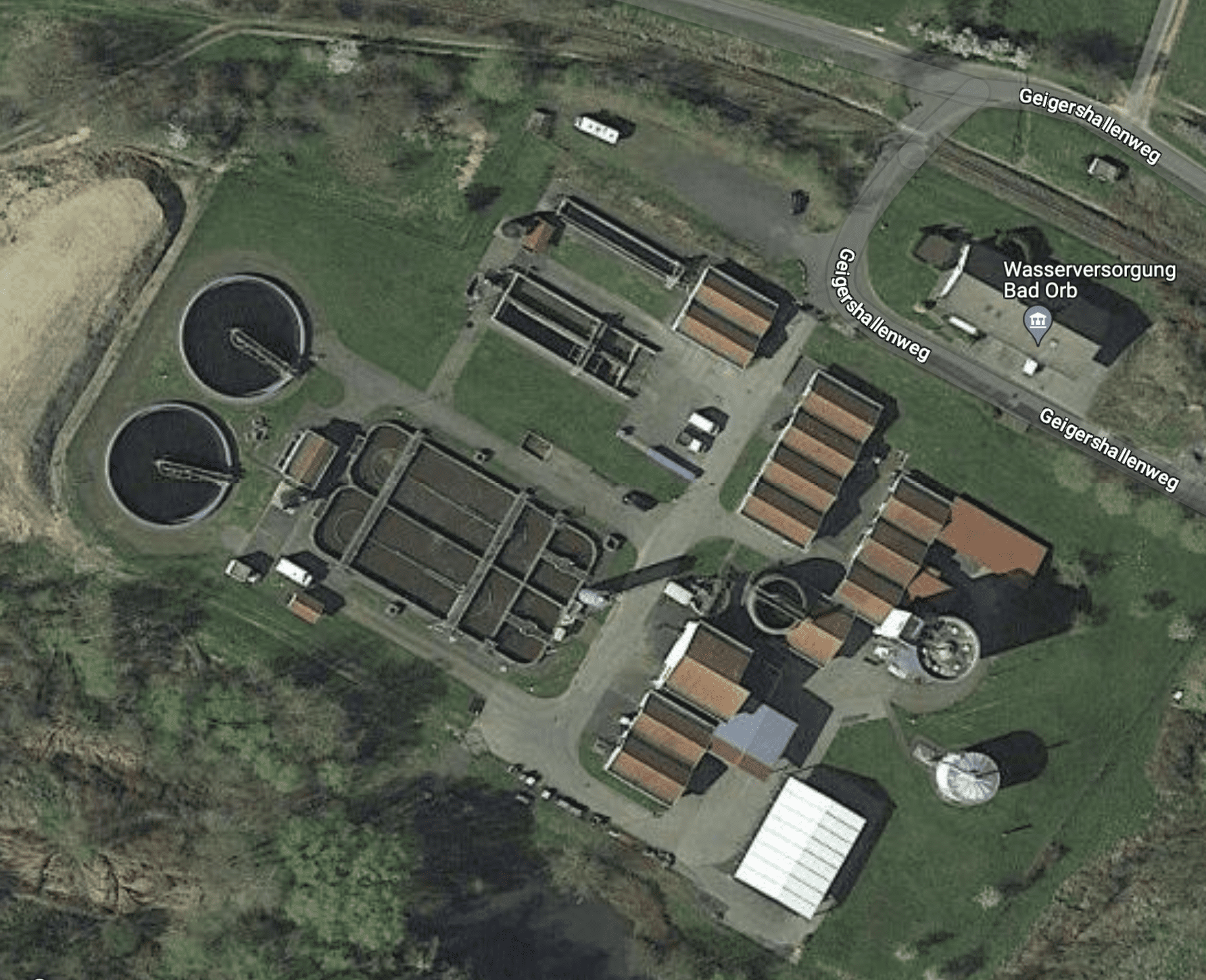

WASTE WATER TREATMENT PLANT – GERMANY

Completed Waste Water Treatment Project: Wald Solms‘ Path to Sustainability.

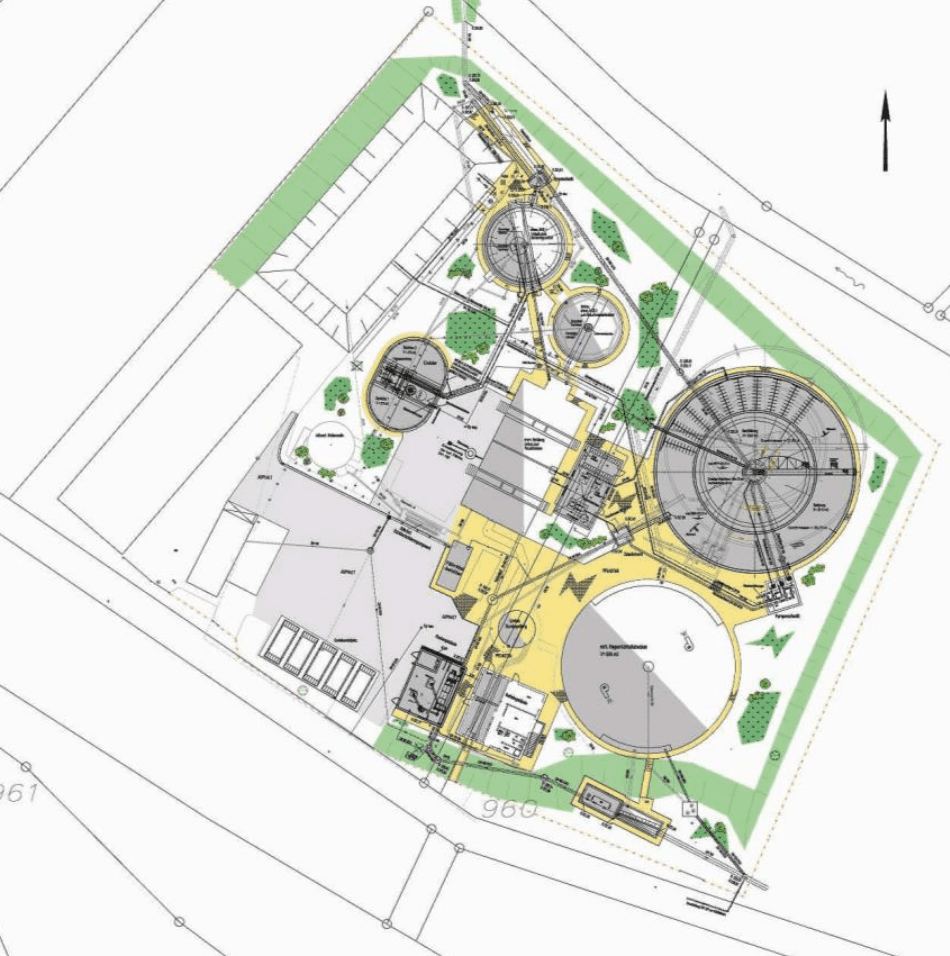

WASTE WATER TREATMENT PLANT

IMPLEMENTATION YEAR: 2006

LOCATION: Wald Solms (Germany)

ACTIVITY: Planning, execution and construction

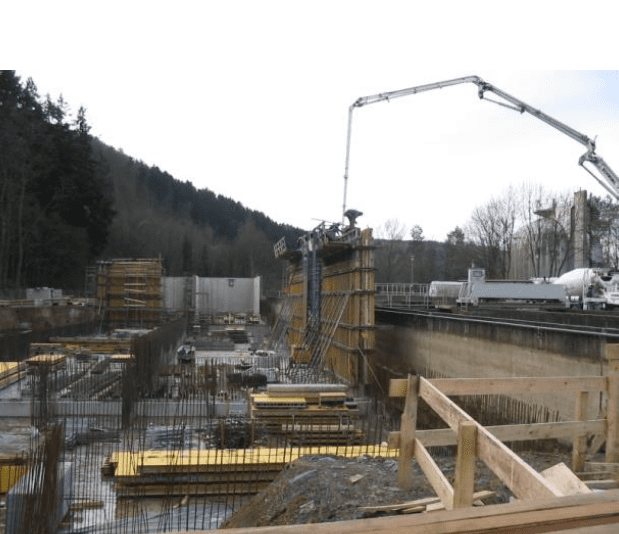

In 2019, we completed the construction of the waste water treatent plant in Wald Solms, Germany. Our team meticulously planned every aspect of the project, ensuring its successful execution and seamless integration into the existing

infrastructure.

The Waste Water Treatment Project in Wald Solms, Germany, completed years ago, marks a significant milestone in the region’s sustainability journey.

This project:

- Safeguarded the environment by effectively treating wastewater and removing contaminants.

- Protected public health by ensuring the safe disposal of wastewater.

- Optimized water resources through responsible reuse and conservation practices.

- Achieved compliance with rigorous environmental standards, promoting sustainability in Wald Solms.

This accomplished project remains a testament to Wald Solms‘ commitment to a cleaner, greener future and sets the foundation for continued environmental stewardship.

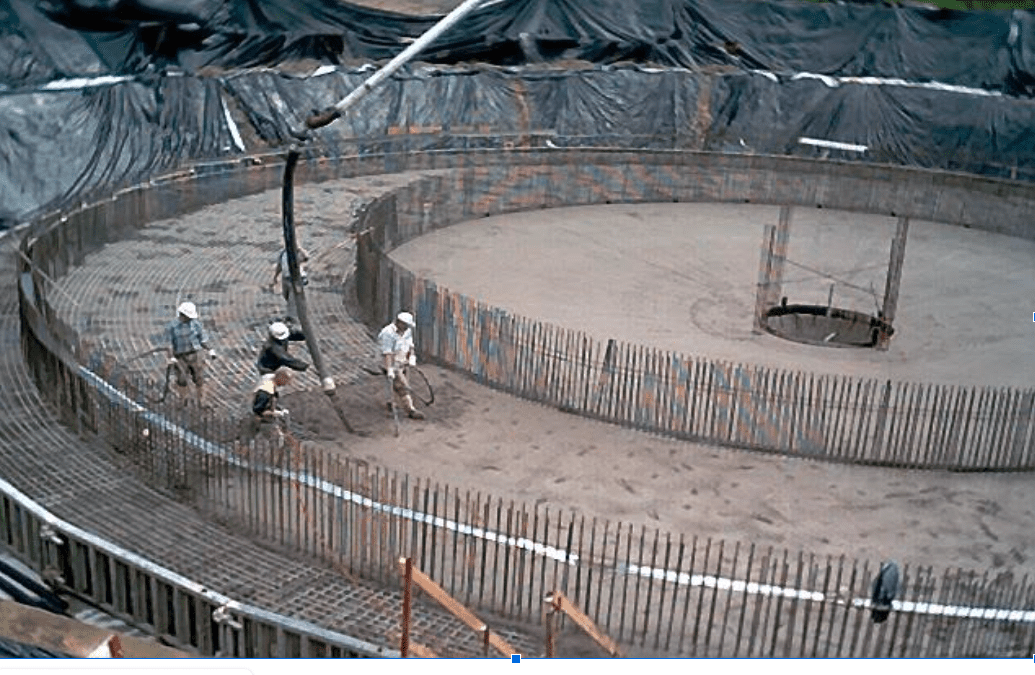

Under the exceptional leadership of Cimec and with the expertise of Dipl. Ing. A. Zörb, the meticulously planned and executed Wald Solms Waste Water Treatment Plant prioritized key technical aspects:

- Engineering Design: An efficient layout and advanced treatment technologies were selected.

- Construction: Precise installation of crucial components was ensured.

- Treatment Process: The plant implemented a multi-stage process, targeting debris, organic matter, and nutrients.

- Automation: Cutting-edge systems monitored and optimized plant processes in real-time.

- Testing: Rigorous assessments validated compliance and confirmed operational functionality.

- Operational Training: Comprehensive training facilitated seamless management and maintenance of the plant.

With the exceptional leadership of Cimec and the expertise of Ing. A. Zörb, the Wald Solms Waste Water Treatment Plant exemplifies technical excellence, delivering efficient treatment processes and sustainable water management for the region. The municipality of Waldsolms operated two wastewater treatment plants in the districts of Brandoberndorf and Kröffelbach to clean the wastewater from the districts of Brandoberndorf, Griedelbach, Hasselborn, and Kröffelbach. However, these treatment plants were no longer sufficiently efficient. It was decided that as part of the expansion of the Brandoberndorf treatment plant, the Kröffelbach facility would be abandoned, and the wastewater from Kröffelbach would be pumped to Brandoberndorf through a DN 150 pressure pipeline for treatment. The Brandoberndorf treatment plant was expanded to ensure that the wastewater from the aforementioned districts would be properly treated according to legal regulations and discharged into the Solmsbach stream.

Initially designed for a population of 3,000, the Brandoberndorf treatment plant did not have adequate capacity for nitrification and denitrification processes.

Operational issues arose due to hydraulic dependencies between the inflows to the two different final clarification basins, as well as with controlling the return sludge flow. Buffering of turbid water during periodic sludge drainage was not possible, leading to significant ammonium loads being discharged into the Solmsbach stream. The design aimed to accommodate a population equivalent of 5,500 residents, including expected process water return loads. The wastewater from Kröffelbach is pumped to the Brandoberndorf treatment plant through a DN 125 pressure pipeline and a pumping station.

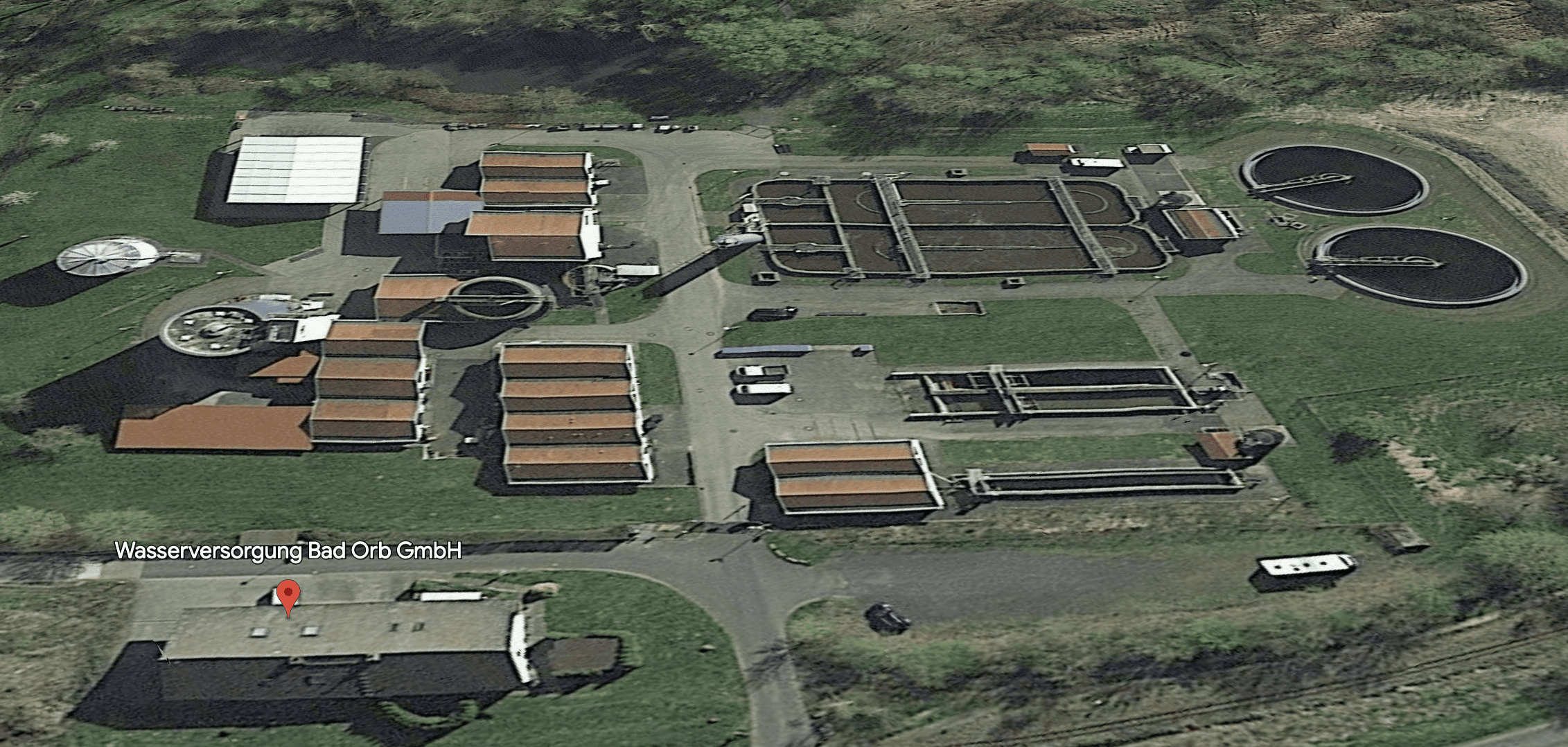

WASTE WATER TREATMENT PLANT – GERMANY

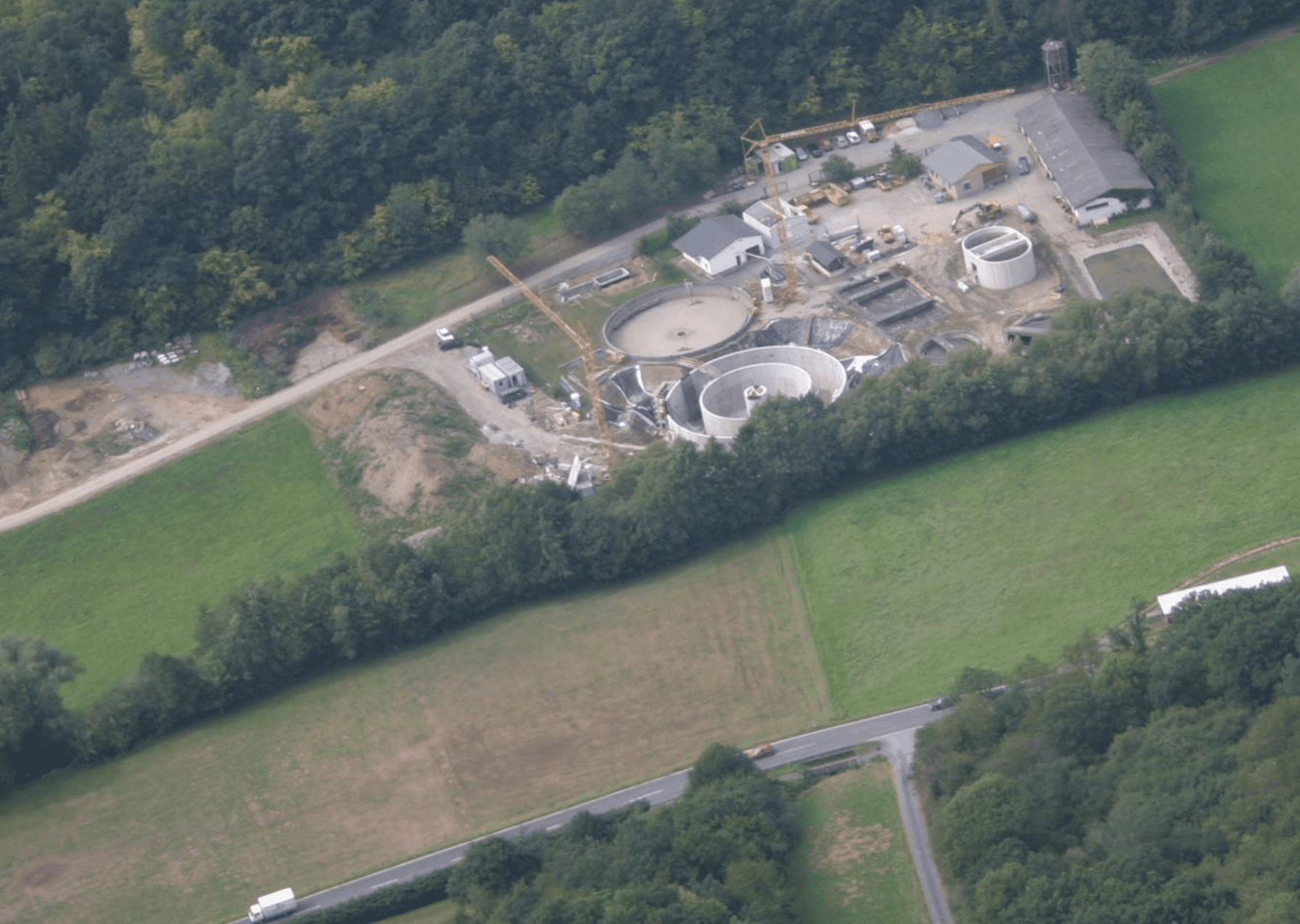

Completed Waste Water Treatment Project: Ulmtal-Lahn‘ Path to Sustainability.

WASTE WATER TREATMENT PLANT

LOCATION: Ulmtal-Lahn (Germany)

ACTIVITY: Planning, execution and construction

In 2014, we completed the construction of the waste water treatent plant in Ulmtal-Lahn, Germany. Our team meticulously planned every aspect of the project, ensuring its successful execution and seamless integration into the existing

infrastructure.

Around 3.5 million cubic meters of wastewater are collected and treated in this way every year.

The completion of the Ulmtal-Lahn Waste Water Treatment Project in Germany years ago represents a major milestone in the region’s sustainability efforts and our ability to advance environmental conservation through effective and sustainable wastewater management.

This project:

- Safeguarded the environment by effectively treating wastewater and removing contaminants.

- Protected public health by ensuring the safe disposal of wastewater.

- Optimized water resources through responsible reuse and conservation practices.

- Achieved compliance with rigorous environmental standards, promoting sustainability in Wald Solms.

- Construction of the Controller-Building

This accomplished project remains a testament to Wald Solms‘ commitment to a cleaner, greener future and sets the foundation for continued environmental stewardship.

Under the exceptional leadership of Cimec and with the expertise of Dipl. Ing. A. Zörb, the meticulously planned and executed Ulmtal-Lahn Waste Water Treatment Plant prioritized key technical aspects:

- Engineering Design: An efficient layout and advanced treatment technologies were selected.

- Construction: Precise installation of crucial components was ensured.

- Treatment Process: The plant implemented a multi-stage process, targeting debris, organic matter, and nutrients.

- Automation: Cutting-edge systems monitored and optimized plant processes in real-time.

- Testing: Rigorous assessments validated compliance and confirmed operational functionality.

- Operational Training: Comprehensive training facilitated seamless management and maintenance of the plant.

With the exceptional leadership of Cimec and the expertise of Ing. A. Zörb, the Ulmtal-Lahn Waste Water Treatment Plant exemplifies technical excellence.

To achieve the goals, a reliable data basis (relief frequency, relief volume of existing relief structures, sewer network data, paved areas, etc.) was essential. In a subsequent inventory, these requirements were specified based

on aerial photo evaluations, pollutant load calculations, and land use plans, and then examined for operational implementation.

Pollutant load simulation calculations for the catchment area revealed the need to create additional retention volume, as the prescribed limits for relief quantities and frequencies were not being met during activation. Accordingly, the wastewater volume for the planned combined sewer overflow (CSO) facility was reduced to 140 l/s according to SMUSI.

Due to the high proportion of extraneous water from the catchment area and depending on the inflow to the wastewater treatment plant of 220 l/s (with adherence to a specific total pollutant load in the final expansion of 220 kg/ha Ared), the project utilized a maximum possible buffer capacity of approximately 2,950 m³ at the treatment plant. This volume was optimized based on cost-effectiveness assessments.

The opportunity to utilize the existing basins (preliminary sedimentation, storm overflow, activated sludge, and preliminary sedimentation basins) was available.

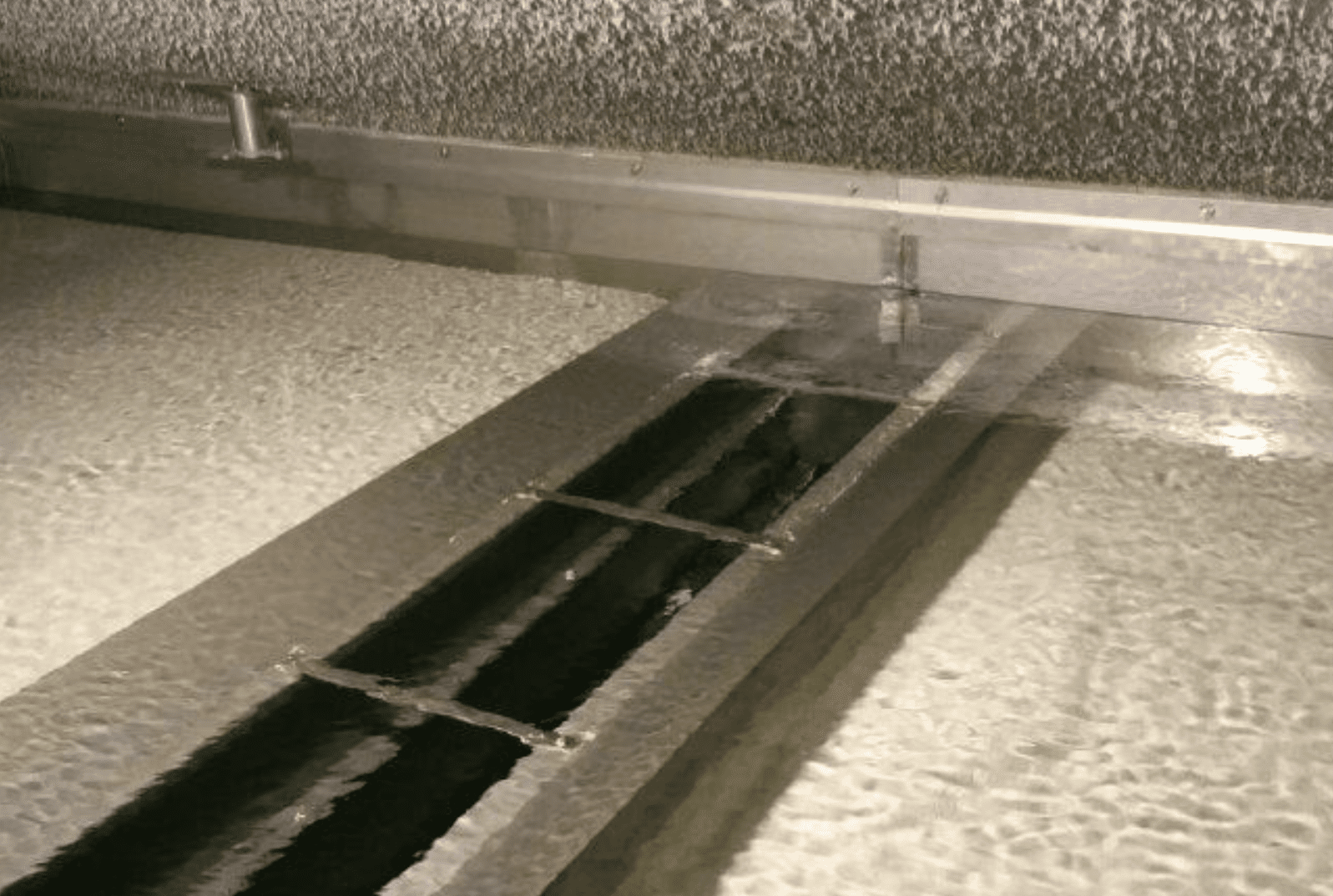

Water supply AND TREATMENT PLANT

in Ortenberg-Usenborn – GERMANY

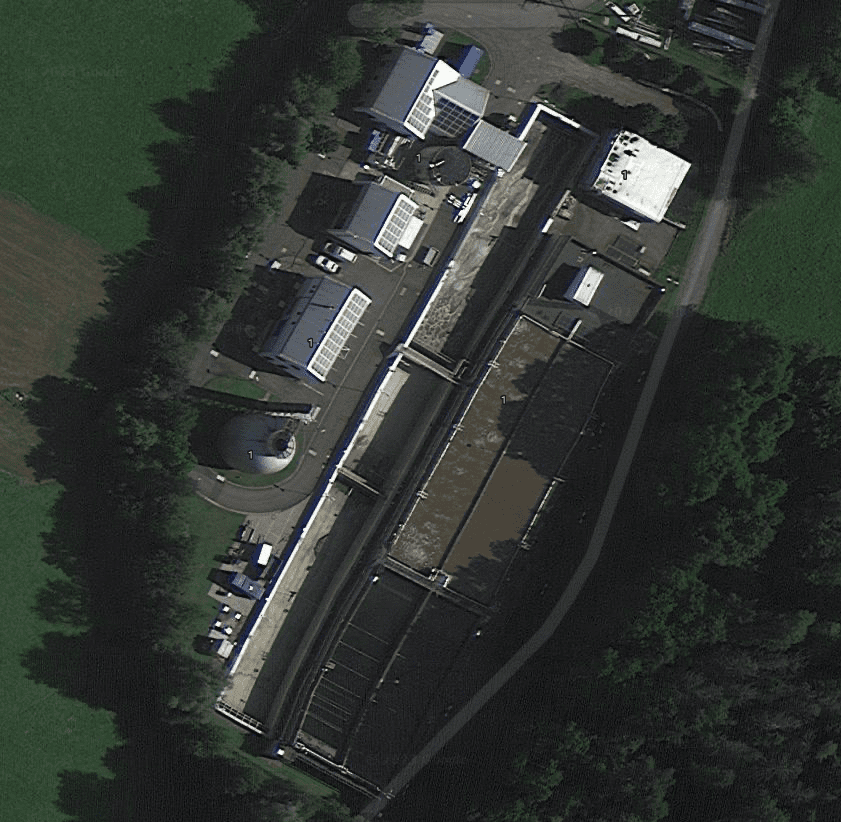

Completed Water supply and Waste Water Treatment Project: Ortenbert-Usenborn

WATER SUPPLY AND WASTE WATER TREATMENT PLANT

LOCATION: Ortenberg-Usenborn (Germany)

ACTIVITY: Planning, execution and construction

In 2015, we completed the construction of the water supply treatent plant in Ortenberg Usenborn, Germany. Our team meticulously planned every aspect of the project, ensuring its successful execution and seamless integration into

the existing infrastructure. The Waste Water Treatment Project in Ortenberg-Usenborn, Germany, completed years ago, marks a significant milestone in the region’s sustainability journey.

Preliminary Assessment: Assessed water supply and wastewater treatment needs, Evaluated available water sources and treatment technologies.

Design and Engineering: Developed an engineering design plan for the plant layout and infrastructure, Designed water intake and treatment systems for supply and wastewater, Ensured compliance with regulations and effluent standards.

Construction and Installation: Executed construction plan and allocated necessary resources, Built infrastructure, including intake structures and treatment tanks, Installed mechanical, electrical, and control systems.

Testing and Commissioning: Conducted comprehensive testing of components and systems, Tested water supply and wastewater treatment processes for efficiency and compliance., Addressed issues and made necessary adjustments.

Under the exceptional leadership of Cimec and with the expertise of Dipl. Ing. A. Zörb, the meticulously planned and executed Ortenberg-Usenborn Waste Water Treatment Plant prioritized key technical aspects:

- Engineering Design: An efficient layout and advanced treatment technologies were selected.

- Construction: Precise installation of crucial components was ensured.

- Treatment Process: The plant implemented a multi-stage process, targeting debris, organic matter, and nutrients.

- Automation: Cutting-edge systems monitored and optimized plant processes in real-time.

- Testing: Rigorous assessments validated compliance and confirmed operational functionality.

Operational Training: Comprehensive training facilitated seamless management and maintenance of the plant.

WASTE WATER TREATMENT PLANT – GERMANY

Completed Waste Water Treatment Project: Giessen (150’000 residents)

WASTE WATER TREATMENT PLANT

LOCATION: Giessen (Germany) – 150’000 residents

ACTIVITY: Potential analyiss, Variant Investigation, Feasibility

In 2001, we completed the Potential analysis of the waste water treatent plant in Giessen (City), Germany. Our team meticulously planned every aspect of the project, ensuring its successful execution and seamless integration into

the existing infrastructure.

The Waste Water Treatment Project in Giessen, completed years ago, marks a significant milestone in the region’s sustainability journey.

This project:

- Variant Investigation about he feasibility

- Continuance / Inventory analysis.

- Optimized water resources through responsible reuse and conservation practices.

- Achieved compliance with rigorous environmental standards, promoting sustainability in Giessen.

This accomplished project remains a testament to Wald Solms‘ commitment to a cleaner, greener future and sets the foundation for continued environmental stewardship.

Under the exceptional leadership of Cimec and with the expertise of Dipl. Ing. A. Zörb, the meticulously planned and executed Giessen Waste Water Treatment Plant prioritized key technical aspects:

- Engineering Design: An efficient layout and advanced treatment technologies were selected.

- Construction: Precise installation of crucial components was ensured.

- Treatment Process: The plant implemented a multi-stage process, targeting debris, organic matter, and nutrients.

With the exceptional leadership of Cimec and the expertise of Ing. A. Zörb, the Wald Solms Waste Water Treatment Plant exemplifies technical excellence, delivering efficient treatment processes and sustainable water management for the region.